II. The temperature pressure relief valve is an essential safety feature that helps prevent the tank from exploding due to excessive pressure or temperature, but it can become clogged with sediment over time.

III. Regular maintenance, including flushing the tank to remove sediment and testing the temperature pressure relief valve to ensure it is functioning properly, can help prevent these issues and extend the life of your water heater.

Sediment removal is a crucial maintenance task for maintaining the efficiency and longevity of your water heater. In this article, we will pioneer the reasons why sediment buildup occurs and how to effectively remove it.

Additionally, we will investigate the importance of the temperature pressure relief valve in ensuring the safety of your water heater. By assimilating these topics, you can empower the performance and safety of your water heater system.

Sediment Removal

Sediment refers to solid particles that accumulate in water heaters over time. These particles can include minerals, debris, and other impurities present in the water supply. Sediment buildup can lead to various issues, affecting the performance and efficiency of your water heater.

1. What is sediment and why does it accumulate in water heaters?

Sediment consists of minerals, such as calcium and magnesium, as well as dirt, sand, and rust particles. These substances enter the water heater through the water supply. As the water heats up, the minerals and impurities settle at the bottom of the tank, forming a layer of sediment.

The accumulation of sediment occurs due to the natural process of water heating. As the water is heated, the dissolved minerals and impurities become less soluble and settle down. Over time, this sediment layer thickens and can negatively impact the performance of the water heater.

2. Signs that your water heater may have sediment buildup

There are several indicators that your water heater may have sediment buildup:

- Fluctuating water temperature

- Reduced hot water supply

- Noises coming from the water heater

- Discolored or cloudy water

If you notice any of these signs, it is essential to address the sediment buildup to prevent further issues and ensure the efficient operation of your water heater.

3. How to flush out sediment from your water heater

Flushing out the sediment from your water heater is a necessary maintenance task that should be performed periodically. Here’s a step-by-step guide to help you:

- Turn off the power supply to the water heater.

- Connect a garden hose to the drain valve located at the bottom of the tank.

- Place the other end of the hose in a suitable drainage area or a bucket.

- Open the drain valve and allow the water to flow out, along with the sediment.

- Once the water runs clear, close the drain valve and remove the hose.

- Turn on the water supply and refill the tank.

Regularly flushing out sediment will help maintain the efficiency and prolong the lifespan of your water heater.

4. Frequency of sediment removal and maintenance tips

The frequency of sediment removal depends on various factors, including the water quality in your area. As a general guideline, it is recommended to flush out the sediment every 6-12 months. Notwithstanding, if you notice any signs of sediment buildup or experience issues with your water heater, it is advisable to perform the maintenance task more frequently.

In addition to regular sediment removal, here are some maintenance tips:

- Check the anode rod and replace if necessary. The anode rod helps prevent corrosion in the tank.

- Insulate the water heater to improve its energy efficiency.

- Monitor the water pressure and temperature settings to avoid excessive strain on the system.

| Frequency | Maintenance Task |

|---|---|

| Every 6-12 months | Flush out sediment from the water heater |

| As needed | Check and replace the anode rod |

| Regularly | Insulate the water heater |

| Ongoing | Monitor water pressure and temperature settings |

Temperature Pressure Relief Valve

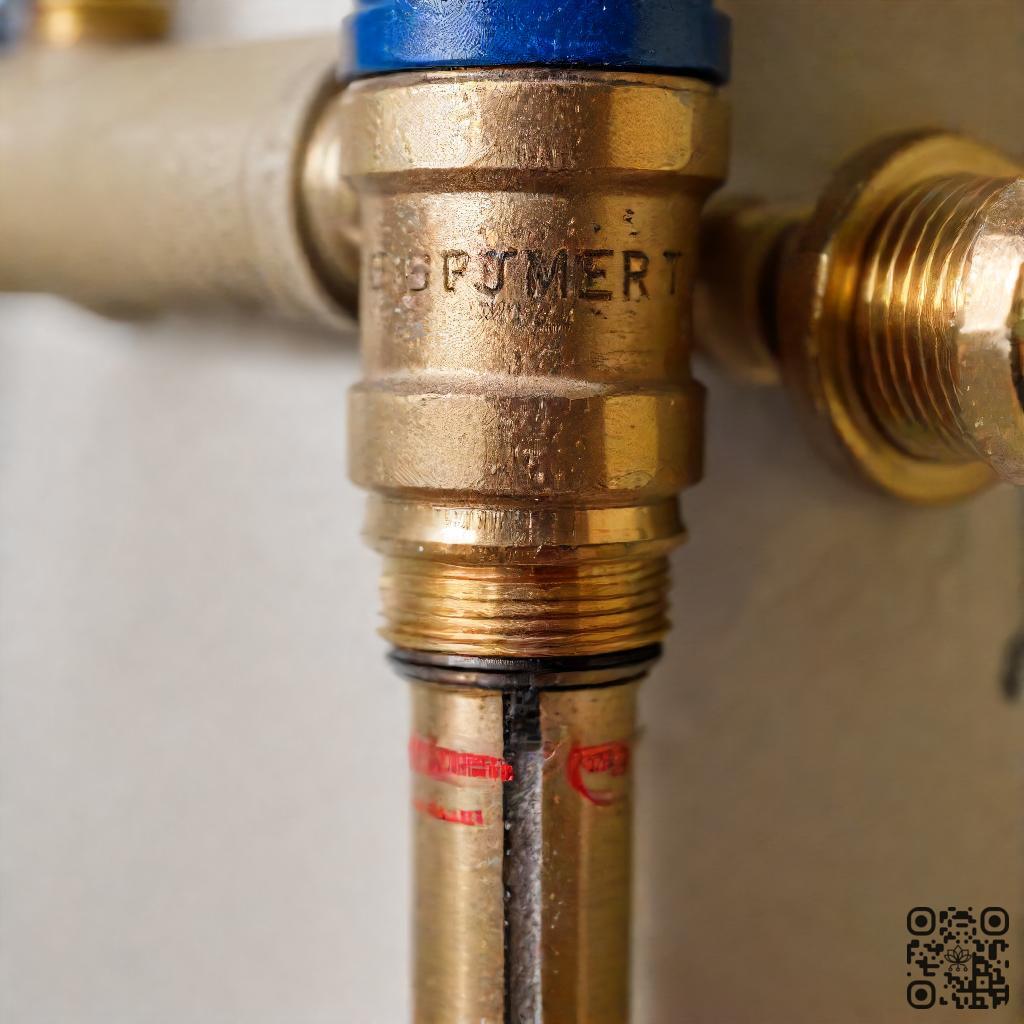

A temperature pressure relief valve is a crucial component of any heating system or water heater. Its main purpose is to ensure the safety of the system by releasing excessive pressure and preventing potential explosions or damage to the equipment. This valve is designed to open automatically when the temperature or pressure inside the system exceeds safe levels, allowing the excess to escape and relieve the stress on the system.

1. What is a temperature pressure relief valve and why is it important?

A temperature pressure relief valve, also known as a TPR valve, is a safety device that protects heating systems and water heaters from dangerous pressure build-up. It plays a vital role in preventing catastrophic failures and potential disasters. Without a properly functioning TPR valve, the pressure inside the system could become too high, leading to explosions or damage to the equipment.

2. Signs that your temperature pressure relief valve may be faulty

It is crucial to regularly inspect and test your TPR valve to ensure its proper functioning. Some signs that your TPR valve may be faulty include:

- Leaking water from the valve

- Inconsistent or no release of pressure during testing

- Visible signs of corrosion or damage

- Inaccurate temperature or pressure readings

3. How to test and replace a temperature pressure relief valve

Testing and replacing a TPR valve should be done by a professional or a qualified technician. Notwithstanding, here are the general steps involved in testing and replacing a TPR valve:

- Turn off the power supply to the heating system or water heater

- Close the water supply valve to the system

- Attach a pressure gauge to the system to monitor the pressure

- Slowly lift the lever on the TPR valve to release pressure

- If the valve does not release pressure or does not seal properly after releasing, it may need to be replaced

- To replace the TPR valve, drain the system, remove the old valve, and install a new one according to manufacturer instructions

4. Frequency of temperature pressure relief valve maintenance and tips for proper usage

Maintenance of the TPR valve is essential to ensure its proper functioning. It is recommended to have a professional inspect and test the valve at least once a year. Additionally, here are some tips for proper usage:

- Do not tamper with or block the TPR valve

- Regularly check for leaks or signs of damage

- Monitor the pressure and temperature of the system

- Follow manufacturer guidelines for maintenance and replacement

Importance of Regular Maintenance

Regular maintenance is essential for the optimal functioning of any system, and this holds true for sediment removal and temperature pressure relief valve maintenance.

1. Benefits of regular sediment removal and temperature pressure relief valve maintenance

Regularly removing sediment from your system and maintaining the temperature pressure relief valve offers numerous benefits. First and foremost, it ensures the longevity of your system by preventing clogs and blockages caused by sediment buildup. This leads to improved efficiency and a longer lifespan for your equipment.

Additionally, regular maintenance helps maintain optimal performance by ensuring that the pressure relief valve is in good working condition. This valve plays a crucial role in releasing excess pressure, preventing potential damage and ensuring the safety of your system.

2. Cost savings and energy efficiency

Regular maintenance not only extends the lifespan of your system but also helps you save on energy costs. By removing sediment and ensuring proper functioning of the temperature pressure relief valve, your system operates more efficiently, reducing energy consumption and ultimately lowering your utility bills.

Furthermore, regular maintenance can identify and address any issues or inefficiencies early on, preventing them from escalating into costly repairs or replacements. Investing in regular maintenance now can save you significant expenses in the long run.

3. Prevention of potential safety hazards

Regular maintenance plays a crucial role in ensuring the safety of your system and those using it. Sediment buildup can lead to pressure imbalances and potential failures, posing a safety risk. By regularly removing sediment and maintaining the temperature pressure relief valve, you minimize the chances of accidents or malfunctions.

Moreover, regular maintenance allows for the detection and rectification of any potential safety hazards. By identifying and addressing issues promptly, you create a safer environment for everyone involved.

DIY vs Professional Maintenance

Relating to maintaining your article, there are two options to consider: DIY or hiring a professional service. Each has its pros and cons, and it’s important to weigh them before making a decision.

1. Pros and Cons of DIY Maintenance

Doing it yourself can be a cost-effective solution, especially if you have the skills and knowledge required. It allows you to have complete control over the process and can be a rewarding experience. That being said, there are some drawbacks to consider. DIY maintenance requires time and effort, and if not done properly, it can lead to further damage or costly repairs. It’s crucial to have the right tools and equipment and be aware of any safety precautions.

2. When to Call a Professional for Sediment Removal or Temperature Pressure Relief Valve Maintenance

Whilst DIY maintenance is a viable option for some tasks, there are instances when it’s best to leave it to the professionals. Sediment removal and temperature pressure relief valve maintenance are two areas where expertise is essential. Sediment buildup can affect the efficiency of your article, and attempting to remove it without proper knowledge can cause damage. Similarly, working with temperature pressure relief valves requires precision, as improper handling can lead to leaks or other issues.

3. Cost Comparison Between DIY and Professional Services

Another important aspect to consider is the cost. DIY maintenance may seem more affordable initially, but it’s essential to factor in the cost of tools, equipment, and any potential mistakes that may require professional assistance later on. In contradistinction, hiring a professional service ensures that the job is done correctly the first time, potentially saving you money in the long run.

| DIY Maintenance | Professional Maintenance |

|---|---|

| Cost-effective | Expertise and knowledge |

| Complete control | Efficient and reliable |

| Time and effort required | Costly upfront |

Common Issues and Troubleshooting

Touching on maintaining your ice cream shop, you may encounter a few common issues that can affect the quality of your icy treats. In this section, we will ponder these issues and provide some troubleshooting tips to help you keep your ice cream shop running smoothly.

1. Sediment Removal and Temperature Pressure Relief Valves

One of the common issues that ice cream shop owners face is sediment buildup in their machines. This can affect the taste and texture of your ice cream, leading to customer dissatisfaction. To address this issue, it’s important to regularly clean and maintain your machines. Follow these steps:

- Turn off the machine and unplug it from the power source.

- Remove any remaining ice cream or mixture from the machine.

- Dismantle the parts that come into contact with the ice cream, such as the mixing blades and the freezing cylinder.

- Soak these parts in warm, soapy water to remove any sediment or residue.

- Use a soft brush to scrub away any stubborn sediment.

- Rinse the parts thoroughly and allow them to air dry before reassembling the machine.

Additionally, another common issue is with temperature pressure relief valves. These valves help regulate the pressure inside the machine and prevent any potential damage. If you notice any issues with your temperature pressure relief valve, such as leaks or inconsistent temperature control, it’s crucial to call a professional for repair.

2. Troubleshooting Tips for DIY Maintenance

During some issues may require professional assistance, there are a few troubleshooting tips that you can try for DIY maintenance:

- Ensure that the power supply to the machine is stable and consistent.

- Check the temperature settings regularly to ensure they are appropriate for the type of ice cream you are making.

- Inspect the machine for any visible signs of damage or wear and tear.

- Clean the machine regularly to prevent any sediment buildup.

- Keep the machine in a well-ventilated area to prevent overheating.

3. When to Call a Professional for Troubleshooting and Repair

In the course of some issues can be resolved through DIY maintenance, there may be instances where it’s best to call a professional for troubleshooting and repair. These include:

- Major leaks or malfunctions in the machine.

- Inconsistent temperature control.

- Unusual noises or vibrations coming from the machine.

- Persistent issues even after following troubleshooting tips.

Bottom Line

Keeping sediment out of your water heater is crucial for its longevity and efficiency. Regular maintenance, such as flushing the tank and installing a sediment filter, can help prevent buildup and extend the life of your water heater.

Additionally, it’s important to ensure that your water heater’s temperature pressure relief valve is functioning properly to prevent dangerous pressure buildup. Regular testing and replacement of the valve can help keep your home safe from potential water heater explosions.

Read More:

1. Sediment Impact On Tankless Water Heater Descaling

2. Sediment Removal And Water Heater Smart Technology Maintenance