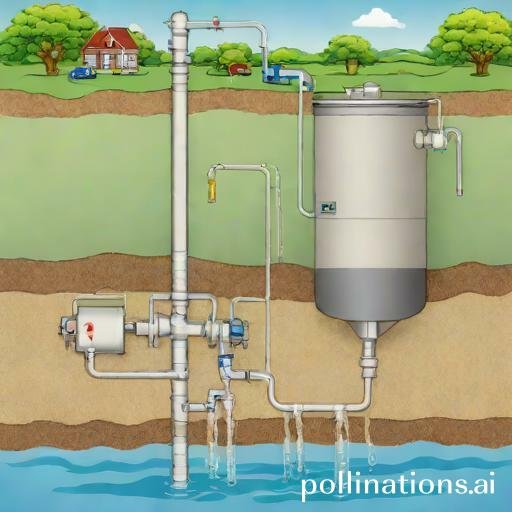

II. Regular maintenance of water heater flues is essential to prevent blockages and ensure proper ventilation, which can prevent carbon monoxide buildup and other dangerous conditions.

III. Proper sediment removal and flue maintenance can help extend the life of your water heater, improve its performance, and keep your home safe from potential hazards.

Sediment buildup can affect the efficiency and lifespan of a water heater, meanwhile neglecting flue maintenance can lead to safety issues. Regularly removing sediment from the tank and ensuring the flue is clear of debris are essential for maintaining a properly functioning water heater.

By acknowledging these two aspects of water heater maintenance, homeowners can ensure optimal performance and safety.

Signs of Sediment Buildup

1. Decreased water pressure

If you are experiencing a decrease in water pressure, it could be a sign of sediment buildup in your water heater. Over time, minerals and debris can accumulate in the tank, causing blockages and hindering the flow of water. This can result in lower water pressure when you turn on your faucets or take a shower.

2. Noisy water heater

Is your water heater making strange noises? This could be another indication of sediment buildup. As sediment settles at the bottom of the tank, it can create a layer that traps heat. When the water heats up, it bubbles and boils through the sediment, causing popping or cracking sounds. If you notice your water heater making more noise than usual, it might be time to address the sediment buildup.

3. Discolored water

Have you noticed discolored water coming out of your taps? Sediment buildup can cause your water to become cloudy, rusty, or even brown in color. This is because the sediment particles can mix with the water, giving it an unpleasant appearance. If you see any discoloration, indispensable to investigate the cause, as it could be a sign of sediment buildup in your water heater.

4. Longer heating time

If it takes longer than usual for your water to heat up, sediment buildup might be to blame. As sediment accumulates in the tank, it acts as an insulator, making it harder for the heating element to warm the water efficiently. This can result in extended heating times and delays in getting hot water when you need it.

5. Increased energy bills

Sediment buildup can also lead to increased energy bills. When the heating element has to work harder to heat the water due to sediment blockages, it consumes more energy. This means that your water heater will be less efficient and use more electricity or gas, resulting in higher energy costs. If you’ve noticed a significant increase in your energy bills, sediment buildup in your water heater could be a contributing factor.

| Signs of Sediment Buildup |

|---|

| 1. Decreased water pressure |

| 2. Noisy water heater |

| 3. Discolored water |

| 4. Longer heating time |

| 5. Increased energy bills |

How to Remove Sediment from Water Heaters

Sediment removal and water heater flue maintenance are essential for ensuring the optimal performance and longevity of your water heater. By complying with these simple steps, you can effectively remove sediment from your water heater and maintain its efficiency.

1. Turn off the power supply

The first step in removing sediment from your water heater is to turn off the power supply. This will ensure your safety during the cleaning process.

2. Drain the tank

Next, you will need to drain the tank. Locate the drain valve at the bottom of the tank and attach a hose to it. Open the valve to allow the water to flow out. Be cautious as the water may be hot.

3. Flush the tank

Once the tank is drained, it’s time to flush out the sediment. Close the drain valve and turn on the cold water supply to the tank. Let the water run for a few minutes to flush out any remaining sediment.

4. Clean the tank and heating elements

After flushing the tank, it’s important to clean both the tank and the heating elements. Remove any sediment or debris that may have accumulated using a soft brush or cloth. Take extra care when cleaning the heating elements to avoid damaging them.

5. Refill the tank

Once the tank and heating elements are clean, close the drain valve and refill the tank with water. Turn on the power supply and allow the water heater to heat the water to the desired temperature.

Water Heater Flue Maintenance

1. Importance of flue maintenance

Maintaining the flue of your water heater is crucial for its optimal performance and safety. The flue is responsible for venting out the harmful gases produced during the combustion process, such as carbon monoxide. Regular maintenance ensures that the flue remains clear and unblocked, allowing for proper ventilation.

2. Signs of flue blockage

Vital to be aware of the signs that indicate a blocked flue. These can include a strong smell of gas, soot or black residue around the water heater, or the presence of carbon monoxide detectors going off. If you notice any of these signs, it is essential to address the issue immediately to prevent any potential danger.

3. How to clean the flue

Cleaning the flue of your water heater is a task that should be performed with caution. Start by turning off the gas supply and allowing the water heater to cool down. Use a chimney brush or a vacuum cleaner to remove any debris or soot that may have accumulated inside the flue. Take care not to damage the flue liner or any other components during the cleaning process.

4. How to check for leaks

Checking for leaks in the flue is an important step in maintenance. Inspect the joints and connections of the flue pipe for any signs of leakage. You can use a solution of soapy water and apply it to the suspected areas. If bubbles form, it indicates the presence of a leak, and immediate action should be taken to address the issue.

5. Importance of professional maintenance

During regular maintenance can be done by homeowners, it is highly recommended to seek professional assistance for thorough inspections and maintenance. A professional technician can ensure that the flue is properly functioning and address any potential issues that may arise. Professional maintenance not only ensures the safety of your water heater but also prolongs its lifespan.

Preventing Sediment Buildup and Flue Blockage

In terms of maintaining your HVAC system, preventing sediment buildup and flue blockage is crucial. Sediment buildup can cause various issues, including reduced efficiency and potential damage to the system. To ensure the longevity and optimal performance of your HVAC system, here are some preventive measures you can take:

1. Regular maintenance schedule

Regular maintenance is key to preventing sediment buildup and flue blockage. It involves cleaning and inspecting your HVAC system at regular intervals to identify any potential issues. By adhering to a maintenance schedule, you can address sediment buildup and flue blockage before they become major problems.

2. Installing a water softener

Hard water contains minerals that can contribute to sediment buildup in your HVAC system. Installing a water softener can help reduce the mineral content in the water, preventing sediment accumulation and ensuring the smooth operation of your system.

3. Using a sediment filter

A sediment filter is a valuable tool in preventing sediment buildup. It captures particles and debris before they can enter your HVAC system, effectively reducing the risk of blockages and improving system efficiency.

4. Installing a flue cap

A flue cap is a protective cover that prevents debris, such as leaves and twigs, from entering the flue pipe. By installing a flue cap, you can prevent blockages and ensure proper airflow, reducing the risk of flue blockage and associated issues.

5. Proper ventilation

Proper ventilation is essential for preventing sediment buildup and flue blockage. Ensure that your HVAC system has adequate airflow and ventilation to prevent stagnant air and promote efficient operation. Regularly check and clean vents and ducts to maintain optimal airflow.

| Preventive Measures | Benefits |

|---|---|

| Regular maintenance schedule | Identify and address issues early |

| Installing a water softener | Reduces mineral content in water |

| Using a sediment filter | Captures particles and debris |

| Installing a flue cap | Prevents debris from entering flue pipe |

| Proper ventilation | Ensures optimal airflow |

Safety Precautions

Pertaining to ensuring safety, it is crucial to follow proper precautions. This section will provide you with a comprehensive guide on how to stay safe when dealing with power supply and chemicals. By adhering to these safety measures, you can protect yourself and others from potential harm.

1. Turn off the power supply

Before you start working with any electrical equipment, always remember to turn off the power supply. This simple step can significantly reduce the risk of electrical shocks and accidents. Make sure to locate the main power switch or unplug the device before proceeding with any maintenance or repairs.

2. Wear protective gear

Protective gear is essential when working with hazardous materials or operating machinery. Always wear the appropriate safety equipment, such as gloves, goggles, or helmets, depending on the nature of your task. These protective measures can shield you from potential injuries and ensure your well-being.

3. Avoid using harsh chemicals

When handling chemicals, it is crucial to be cautious. Avoid using harsh or toxic chemicals unless absolutely necessary. If you must use them, ensure proper ventilation and follow the instructions carefully. Using milder alternatives or eco-friendly products whenever possible can minimize the risks associated with chemical exposure.

4. Hire a professional if unsure

If you are unsure about a particular task or lack the necessary expertise, it is always wise to seek professional help. Hiring a qualified technician or electrician can prevent accidents and ensure the job is done correctly. Don’t hesitate to ask for assistance when needed to prioritize your safety.

5. Follow manufacturer’s instructions

Manufacturers provide detailed instructions for a reason. Always read and follow the manufacturer’s instructions when using any equipment or products. These guidelines are designed to maximize safety and prevent potential hazards. Ignoring or disregarding these instructions can lead to accidents and damage.

| Precaution | Description |

|---|---|

| Turn off the power supply | Ensure to switch off the power before working with electrical equipment. |

| Wear protective gear | Use appropriate safety equipment like gloves, goggles, or helmets. |

| Avoid using harsh chemicals | Minimize the use of toxic chemicals and opt for safer alternatives. |

| Hire a professional if unsure | Seek expert assistance if you are uncertain about a task. |

| Follow manufacturer’s instructions | Read and adhere to the instructions provided by the manufacturer. |

Bottom Line

Regular sediment removal and water heater flue maintenance are crucial for ensuring the efficient and safe operation of your water heater. Neglecting these tasks can lead to reduced performance, increased energy bills, and even dangerous carbon monoxide leaks. It is recommended to flush your water heater at least once a year and have a professional inspect and clean your flue every two to three years. Additionally, integral to be aware of the signs of sediment buildup and flue blockages, such as strange noises, foul odors, and visible rust or debris. By taking these preventative measures, you can extend the lifespan of your water heater and protect the health and safety of your household.

Read More:

1. Sediment Impact On Tankless Water Heater Flow Sensor

2. Sediment Removal And Water Heater Insulation Maintenance